Top 10 Stainless Steel Valves for Every Application You Need to Know

When it comes to industrial applications, the choice of materials and components is crucial for ensuring efficiency and longevity. One essential component that frequently comes into play is stainless steel valves. Renowned for their durability, resistance to corrosion, and versatility, stainless steel valves are vital in a myriad of applications ranging from water treatment to chemical processing. Understanding the different types of stainless steel valves and their specific use cases can significantly impact the performance and reliability of an entire system.

This guide will delve into the top 10 stainless steel valves that cater to varied operational needs. Each type of valve serves a unique purpose, whether it's controlling flow, regulating pressure, or preventing backflow. The proper selection and implementation of these valves can enhance safety, efficiency, and maintenance in any operation. As industries continue to seek out robust solutions, knowing the best stainless steel valves available makes all the difference in achieving optimal results and meeting project demands.

Understanding Stainless Steel Valves: Types and Benefits

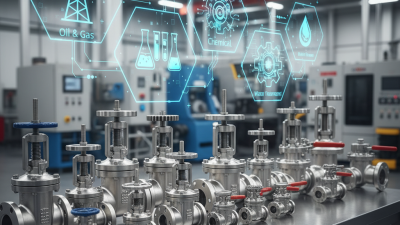

Stainless steel valves are critical components across various industries due to their exceptional properties and versatility. These valves are primarily categorized into several types, including ball valves, gate valves, globe valves, and check valves, each serving unique functions. According to a report by MarketsandMarkets, the global stainless steel valves market is projected to reach $11.3 billion by 2025, highlighting the growing demand driven by their durability and resistance to corrosion, which are essential in environments such as oil and gas, chemical processing, and wastewater management.

The benefits of stainless steel valves extend beyond mere durability. Their ability to withstand extreme temperatures and pressures makes them suitable for high-performance applications. For instance, studies have shown that stainless steel valves can endure temperatures up to 1,500°F (815°C) and pressures exceeding 1,500 psi, making them indispensable in high-stakes environments. Additionally, their low maintenance requirements contribute to long-term cost savings and operational efficiency. As industries continue to emphasize sustainability and safety, the importance of stainless steel valves will only increase, reinforcing their role as a cornerstone of modern engineering solutions.

Key Factors to Consider When Choosing Stainless Steel Valves

When selecting stainless steel valves for your applications, several key factors must be taken into account to ensure optimal performance and durability. First and foremost, consider the valve type that best suits your needs, whether it be ball, gate, globe, or check valves. Each type serves a unique purpose in controlling the flow of liquids and gases, so understanding the specific requirements of your system will guide your choice.

Another crucial aspect is the pressure and temperature rating of the valves. Stainless steel valves are made to endure various operating conditions, but it's essential to match the valve specifications with the demands of your application. Additionally, assess the compatibility of the stainless steel material with the fluids being transported. For corrosive environments or high-temperature applications, selecting the appropriate grade of stainless steel can significantly affect the longevity and performance of the valve.

Lastly, installation and maintenance considerations should be part of your decision-making process. Ensure that the design of the valve allows for easy installation within your system, and consider how straightforward it will be to maintain and repair over time. Proper maintenance can extend the life of your stainless steel valves, making it important to choose designs that facilitate this process. By evaluating these factors, you can make an informed choice that meets your operational needs effectively.

Top 10 Applications of Stainless Steel Valves in Various Industries

Stainless steel valves play an indispensable role across a myriad of industries, thanks to their durability, resistance to corrosion, and ability to maintain structural integrity under high pressure. In the oil and gas sector, for instance, the use of stainless steel valves is critical for ensuring safety and efficiency in pipelines, with market reports indicating that the global market for industrial valves is expected to reach approximately $90 billion by 2025, driven largely by the oil and gas industry. These valves are preferred for their reliability in handling aggressive media, which makes them essential for maintaining operational integrity in challenging environments.

Similarly, the food and beverage industry relies heavily on stainless steel valves to meet stringent hygiene standards while ensuring smooth operational flow. According to industry standards, stainless steel is ideal for applications involving food processing equipment, as it can withstand high temperatures and rigorous cleaning processes. A recent survey found that nearly 70% of food processing plants utilize stainless steel valves to prevent contamination and streamline operations, highlighting their vital role in maintaining product quality and compliance with health regulations.

In pharmaceutical manufacturing, stainless steel valves also prevent contamination, which is crucial for producing safe and effective medications. As such, these valves not only facilitate operational efficiency but also uphold the highest safety standards across industries.

Detailed Review of the Leading Stainless Steel Valve Brands

Stainless steel valves are crucial components in various industries, including oil and gas, water treatment, and food processing, due to their excellent resistance to corrosion and high temperatures. A recent market analysis from a leading industry research firm highlights that the global stainless steel valve market is projected to grow significantly, reaching an estimated value of $20 billion by 2025. This growth is driven by increased demand for reliable and durable valves to enhance system efficiency and safety in industrial applications.

When evaluating the top stainless steel valve brands, key performance metrics include durability, operating pressure, and resistance to aggressive environments. Research indicates that valves constructed from high-grade stainless steel, such as 316 or 304 grades, often demonstrate superior longevity and performance under extreme conditions. Additionally, the integration of advanced manufacturing technologies has led to valves that maintain tighter tolerances and improved flow characteristics, which are essential for optimizing operational efficiency and minimizing maintenance costs. As industries continue to evolve, the demand for cutting-edge valve technology remains a significant focus for manufacturers striving to meet rigorous industry standards and customer expectations.

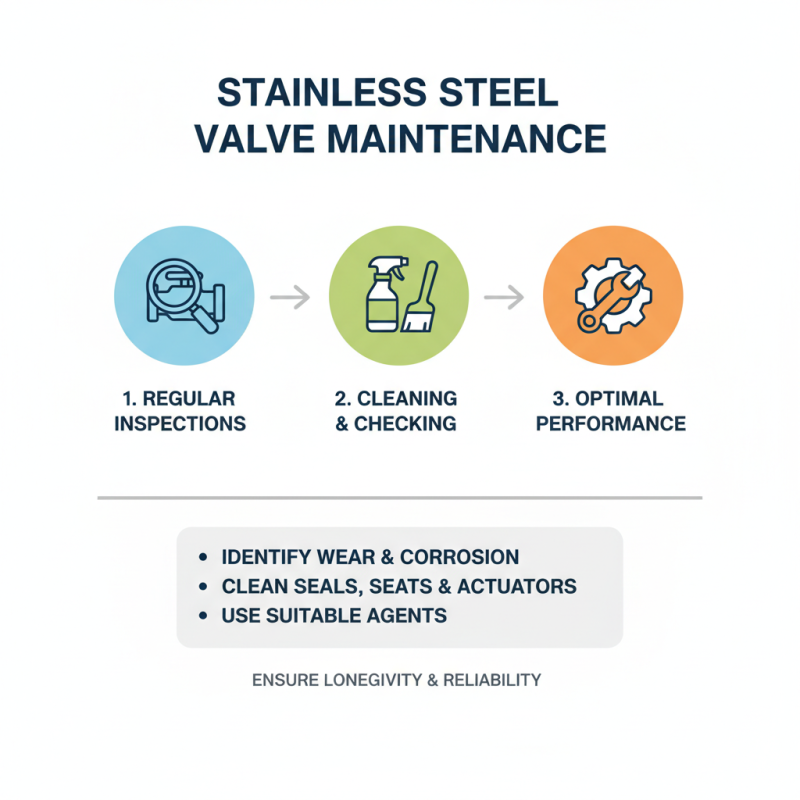

Maintenance Tips for Ensuring Optimal Performance of Stainless Steel Valves

Maintaining stainless steel valves is crucial for ensuring their optimal performance and longevity across various applications. Regular inspections can help identify wear, corrosion, or debris buildup that may hinder functionality. A systematic schedule for cleaning and checking valve components should be established, focusing on areas such as seals, seats, and actuators. Utilizing the appropriate cleaning agents can effectively remove contaminants without damaging the stainless steel surface.

In addition to routine checks, lubrication plays a vital role in maintaining the operational efficiency of stainless steel valves. Using the right type of lubricant can reduce friction between moving parts, thereby minimizing wear and tear. It's also important to ensure that valves are operated within their design parameters to prevent undue stress that could lead to premature failure. Whenever a valve is disassembled for maintenance, it is essential to inspect all components thoroughly and replace any parts that show signs of significant wear. By following these maintenance tips, users can significantly enhance the performance and lifespan of stainless steel valves in their operations.

Related Posts

-

2025 How to Choose the Right Stainless Steel Valves for Your Industry Needs

-

Understanding the Benefits of Using Ball Check Valves in Fluid Control Systems

-

Top 10 Ball Valves for Industrial Applications You Should Consider

-

Top 10 Ball Valves You Need to Know for Your Next Project

-

Top 10 Tips for Choosing the Best Industrial Check Valves for Your Needs

-

2025 How to Choose the Right Steel Ball Valve for Your Industrial Needs