Top 5 Pressure Valves: Choosing the Best for Your Industrial Needs

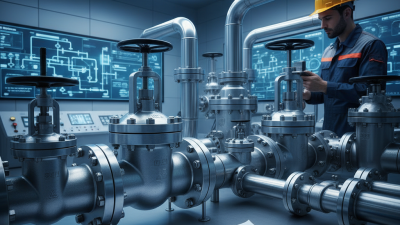

When it comes to industrial applications, the importance of high-quality pressure valves cannot be overstated. These components play a crucial role in maintaining safety, efficiency, and reliability in various systems, from oil and gas pipelines to water treatment facilities. In 2025, the market for pressure valves is expected to evolve significantly, with advancements in technology leading to improved designs and performance. As industries seek to optimize their operations, choosing the right pressure valves becomes essential for ensuring safety and adherence to regulatory standards.

In this article, we will explore the top five pressure valves that stand out in the current market. Each of these valves has been meticulously evaluated based on criteria such as durability, functionality, and cost-effectiveness. Our goal is to provide industry professionals with comprehensive insights into the best options available, helping them make informed decisions that align with their specific industrial needs. Whether you are upgrading existing systems or designing new applications, understanding the features and benefits of these leading pressure valves will empower you to enhance performance and maintain operational integrity.

Essential Features to Consider When Selecting Pressure Valves for Industrial Applications

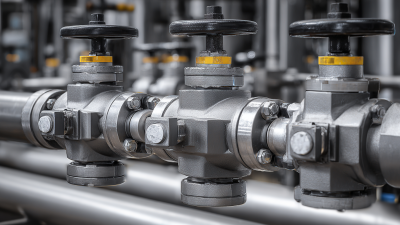

When selecting pressure valves for industrial applications, it's essential to consider several key features that ensure optimal performance and safety. One important factor is the material of the valve; for instance, PTFE (polytetrafluoroethylene) is widely recognized for its excellent chemical resistance and is used in valve seats to prevent reverse flow. Choosing the right material significantly impacts the valve's longevity and capability to handle various fluids in demanding environments.

Another critical aspect is the compliance with industry standards, such as ASTM or ISA-75 and ISA-96 series, which govern the design, testing, and performance of valves and their components. Adhering to these standards not only guarantees reliability and efficiency but also ensures the safety of the entire fluid process system.

Additionally, with the rising integration of smart technology in industrial applications, opting for valves that can accommodate advanced control systems or predictive maintenance techniques will enhance operational effectiveness. Thus, evaluating these essential features will lead to better decision-making, resulting in improved industrial outcomes.

Comparative Analysis of the Top 5 Pressure Valve Brands in the Market

When it comes to selecting the ideal pressure valves for industrial applications, understanding the comparative strengths and weaknesses of leading brands is crucial. Each brand brings a unique combination of technology, reliability, and cost-effectiveness to the table. For example, Brand A is recognized for its innovative spring-loaded technology, which ensures precise pressure control, making it a favorite in chemical processing industries. Meanwhile, Brand B excels in durability, offering valves made from high-grade materials that withstand extreme conditions, thus appealing to industries like oil and gas.

Additionally, Brand C focuses on user-friendliness and quick installation, catering to industries that require fast turnaround and minimal downtime. Its valves come equipped with fail-safe mechanisms, enhancing safety in critical operations. On the other hand, Brand D is lauded for its extensive customer support and custom solutions, making it the go-to choice for businesses that need tailored valve configurations. Lastly, Brand E combines affordability with versatility, enabling it to penetrate diverse sectors without sacrificing quality. This comparative analysis aids businesses in making informed decisions, ultimately optimizing their operational efficiency.

Top 5 Pressure Valves: Choosing the Best for Your Industrial Needs

| Feature | Valve A | Valve B | Valve C | Valve D | Valve E |

|---|---|---|---|---|---|

| Max Pressure (PSI) | 250 | 300 | 200 | 350 | 400 |

| Material | Stainless Steel | Bronze | Aluminum | Carbon Steel | PVC |

| Size Range (inches) | 1 - 6 | 1 - 8 | 1/2 - 4 | 2 - 10 | 3/4 - 6 |

| Temperature Range (°F) | -20 to 400 | 0 to 300 | -20 to 250 | -40 to 500 | 0 to 150 |

| Price (USD) | $150 | $180 | $120 | $200 | $100 |

Impact of Material Selection on Pressure Valve Performance and Longevity

The material selection for pressure valves plays a crucial role in determining their performance and longevity in industrial applications. In the oil and gas sector, where reconditioning projects aim to modernize critical infrastructure, the choice of materials directly impacts operational efficiency and safety. According to recent industry reports, titanium castings are gaining traction due to their reliability and cost-effectiveness, particularly in environments where seawater corrosion is a concern. This shift suggests that industries are prioritizing sustainable practices while enhancing the durability of their equipment.

Moreover, the use of advanced materials can significantly improve the performance of pressure valves across various sectors. For instance, the application of unique materials such as fish swim bladders as valve leaflets has been shown to enhance the durability of transcatheter aortic valve replacement devices, demonstrating innovative approaches in material engineering. Research indicates that these advanced composites provide superior fatigue resistance, making them a valid consideration for industries that require long-lasting and high-performing pressure valves. Understanding the impacts of different materials not only aids in selecting the right valve but also contributes to the overall sustainability goals in industrial operations.

Common Applications and Best Practices for Using Industrial Pressure Valves

When selecting industrial pressure valves, it's essential to understand their common applications and best practices to ensure efficiency and safety in operations. Pressure valves are crucial in various industries including oil and gas, water treatment, and manufacturing. According to a recent report by Grand View Research, the industrial valves market is projected to reach USD 90.5 billion by 2027, indicating a strong demand for reliable pressure control systems. These valves help maintain pressure levels within specified limits, preventing potential hazards and optimizing production processes.

Best practices for utilizing industrial pressure valves can significantly impact operational performance. Regular maintenance is vital; a study by the International Society of Automation suggests that predictive maintenance can reduce equipment failure by up to 30%. Additionally, understanding the specific requirements of your system—such as pressure range, fluid type, and temperature—can guide you in selecting the right valve.

Employing advanced technologies like IoT sensors can also enhance monitoring and control, ensuring that pressure valves operate within optimal parameters, thus reducing downtime and increasing overall productivity.

Innovations in Pressure Valve Technology and Their Benefits for Industries

Innovations in pressure valve technology are revolutionizing industrial applications, providing enhanced safety, efficiency, and reliability. Recent studies estimate that advanced pressure valves can improve process efficiency by up to 30%, significantly reducing operational costs for industries such as oil and gas, pharmaceuticals, and food processing. Smart pressure valves equipped with IoT sensors allow for real-time monitoring and data analytics, enabling predictive maintenance that can decrease downtime by about 25%.

Furthermore, manufacturers have integrated materials science advancements, resulting in valves that withstand higher temperatures and pressures while also minimizing the risk of leaks. For example, valves made from advanced composites can endure extreme environments, boosting their lifespan by an impressive 40%, according to the latest industry reports. These innovations not only enhance the reliability of industrial operations but also contribute to sustainability efforts by decreasing waste and energy consumption, which is pivotal in a world increasingly focused on reducing its carbon footprint.

Top 5 Pressure Valves: Performance Comparison

This chart illustrates the pressure capacity and efficiency ratings of the top 5 pressure valves available in the market. The data shows the maximum pressure each valve can handle (in PSI) and their efficiency ratings (on a scale from 1 to 10).

Related Posts

-

Top 5 Benefits of Using Carbon Steel Ball Valves for Industrial Applications

-

2025 How to Choose the Right Steel Ball Valve for Your Industrial Needs

-

Exploring the Future of Industrial Valves: Innovations and Trends Shaping the Industry

-

Understanding the Benefits of Using Ball Check Valves in Fluid Control Systems

-

The Rising Demand for Globe Valves in Industrial Applications and Their Key Performance Metrics

-

Top 10 Reasons Why Steel Ball Valves Are Essential for Your Industrial Applications