Top 10 Gate Valve Types Every Engineer Should Know for Optimal Performance

Gate valves are essential components in various engineering applications, primarily used to regulate the flow of fluids in pipelines. Their design, which includes a wedge or gate that slides into the flow path, allows for minimal flow resistance when fully opened. Understanding the different types of gate valves is crucial for engineers who aim to achieve optimal performance in their systems. Each type offers unique advantages and is suited for specific applications, making it essential to choose the right valve based on the operational requirements and environmental conditions.

In this article, we explore the top 10 gate valve types that every engineer should be familiar with. From rising stem to non-rising stem designs, each valve type presents its own set of characteristics and benefits. By gaining insight into these variations, engineers can make informed decisions that enhance efficiency, safety, and reliability in fluid control systems. Whether dealing with high-pressure scenarios or corrosive environments, understanding the nuances of gate valves allows for improved system performance and longevity, ensuring that engineering projects meet stringent standards and expectations.

Overview of Gate Valves and Their Functionality

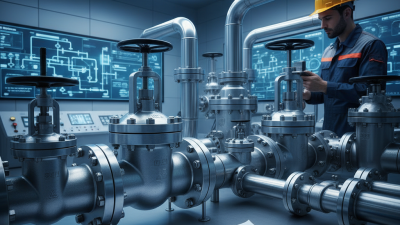

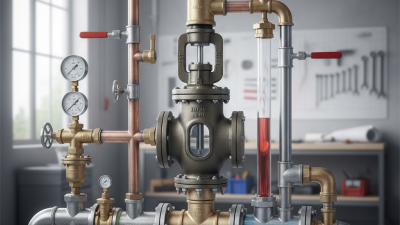

Gate valves are vital components in various fluid control systems, widely used in pipelines to regulate flow. Their primary function is to enable or disable the flow of liquids and gases, providing a reliable mechanism for isolation rather than throttling, which means they are most effective when fully open or fully closed. The design of a gate valve typically features a flat piece—the gate—which moves vertically within the valve body. This allows for minimal resistance to flow when the valve is in the open position, making it suitable for services where low pressure drop and flow efficiency are crucial.

Understanding the functionality of gate valves involves recognizing the different types available and their specific applications. For instance, wedge gate valves are commonly used for their robust sealing capabilities and ability to handle high-pressure environments, while rising stem gate valves offer visual indication of their open or closed status due to the stem's position. Moreover, non-rising stem valves are advantageous in situations where vertical space is limited, allowing for efficient operation within confined areas. Engineers must choose the appropriate type based on factors like fluid characteristics, pressure ratings, and installation conditions to ensure optimal performance and longevity of the valve in the system.

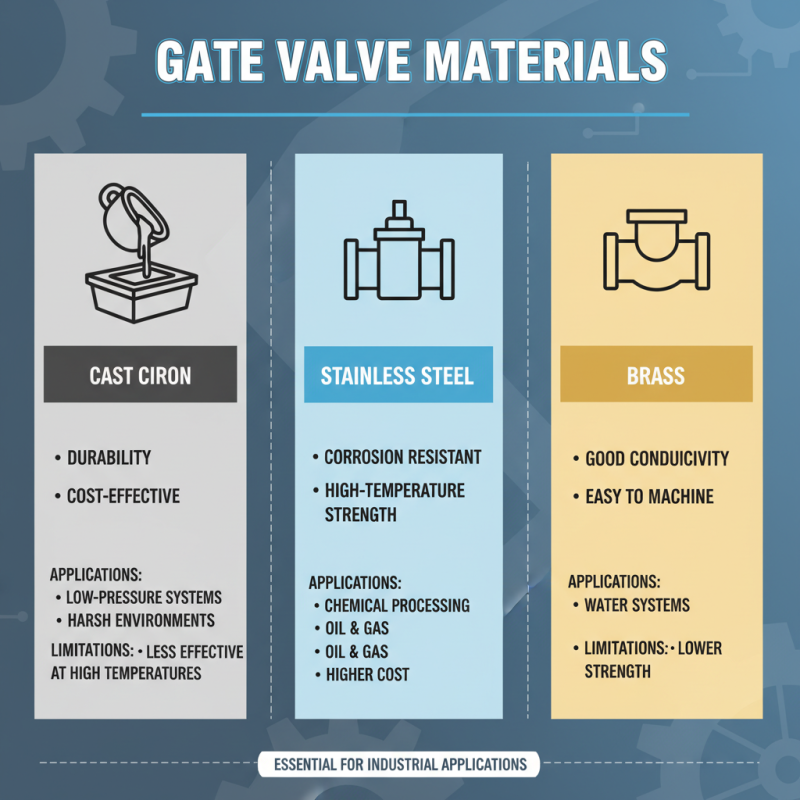

Common Materials Used in Gate Valve Manufacturing

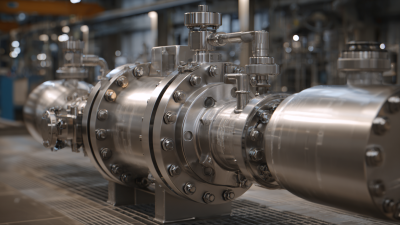

Gate valves are essential components in various industrial applications, and their performance largely depends on the materials used in their manufacturing. Common materials for gate valves include cast iron, stainless steel, and brass, each selected for its specific advantages. Cast iron is known for its durability and cost-effectiveness, making it suitable for low-pressure applications. It can withstand harsh environments but is less effective in high-temperature scenarios.

Stainless steel is a preferred choice for gate valves due to its excellent corrosion resistance and strength, which is crucial for high-pressure and high-temperature applications. The ability to resist oxidation and rust allows stainless steel gate valves to thrive in industries such as oil and gas, chemicals, and water treatment. Brass, often used for smaller valves, offers good corrosion resistance and malleability, making it advantageous for plumbing and HVAC systems. Each of these materials contributes to the overall functionality and longevity of gate valves, ensuring optimal performance tailored to the specific requirements of various engineering projects.

Types of Gate Valves: A Comprehensive Breakdown

Gate valves are crucial components in various industrial applications, serving as isolating devices that facilitate on-off control within fluid systems. A comprehensive understanding of the different types of gate valves is vital for engineers aiming to optimize performance and ensure system reliability. Common types include rising stem, non-rising stem, wedge gate, and parallel slide gate valves, each designed with specific functionalities and operational advantages. For instance, rising stem gate valves are preferred in high-pressure applications due to their capability to provide visual confirmation of valve status, while non-rising stem valves are better suited for space-constrained environments.

According to the latest report by the Global Valve Market, gate valves represent approximately 25% of the total valve demand, underlining their significance in sectors such as oil and gas, water treatment, and power generation. Additionally, advancements in materials and design have led to the development of resilient gate valves, which enhance longevity and reduce maintenance costs. Data indicates that the use of innovative materials can lead to a decrease in maintenance incidents by up to 40%, making it imperative for engineers to select the appropriate valve type based on their specific operational requirements. Thus, understanding the nuances of gate valve types enables engineers to enhance system efficiency and reliability significantly.

Top 10 Gate Valve Types Every Engineer Should Know for Optimal Performance

| Gate Valve Type | Material | Pressure Class | Size Range | Application |

|---|---|---|---|---|

| Wedge Gate Valve | Carbon Steel | 150-2500 psi | 2" - 48" | Water, Oil, Gas |

| Parallel Gate Valve | Stainless Steel | 150-600 psi | 4" - 20" | Power Plants |

| Split Wedge Gate Valve | Alloy Steel | 300-1500 psi | 3" - 36" | Chemical Industry |

| Rising Stem Gate Valve | Carbon Steel | 150-3000 psi | 1" - 24" | HVAC Systems |

| Non-Rising Stem Gate Valve | Ductile Iron | 150-400 psi | 2" - 12" | Municipal Water |

| Gate Valve with Osnabrück | Bronze | 150 psi | 1" - 8" | Irrigation |

| Butterfly Gate Valve | Plastic | 150-500 psi | 2" - 12" | Wastewater Treatment |

| Knife Gate Valve | Carbon Steel | 150-300 psi | 4" - 24" | Slurry and Sludge |

| Safety Gate Valve | Stainless Steel | 150-600 psi | 1" - 10" | Explosion Protection |

Applications of Different Gate Valve Types in Engineering

Gate valves are essential components in various engineering applications, providing reliable control of fluid flow. Different types of gate valves are designed to meet specific operational needs across multiple industries. For instance, rising stem gate valves are commonly used in water supply systems because their clearly visible stem position allows operators to easily gauge flow status. These valves excel in on/off applications, where a straight-line flow path facilitates minimal pressure drop.

On the other hand, non-rising stem gate valves find their application in environments where space is limited, such as underground pipelines or tight mechanical spaces. Their compact design makes them ideal for use in industrial settings where maintenance spaces are restricted. Additionally, wedge gate valves are highly favored in high-pressure applications due to their robust construction, ensuring effective sealing and durability. By understanding the distinct functionalities and applications of various gate valve types, engineers can make informed decisions that enhance both system efficiency and performance.

Top 10 Gate Valve Types Every Engineer Should Know for Optimal Performance

Best Practices for Installing and Maintaining Gate Valves

When it comes to installing and maintaining gate valves, engineers must adhere to best practices to ensure optimal performance and longevity. First and foremost, proper installation begins with thorough system assessments. Before any valve is placed, it's crucial to clean the pipeline and remove any debris that could interfere with the valve function. Aligning the valve correctly is also essential; ensuring that it is positioned to minimize stress on the valve body and seals will reduce the risk of leaks and mechanical failure.

Routine maintenance is equally important in the lifecycle of gate valves. Engineers should develop a schedule for regular inspections, focusing on identifying signs of wear or damage. Lubricating the valve stem and checking for tight seals can prevent corrosion and ensure smooth operation. It is also advisable to periodically exercise the valve—opening and closing it fully—to prevent it from seizing, which is a common issue in valves that are infrequently used. By following these best practices for installation and maintenance, engineers can contribute to the reliable performance of gate valves in various applications.

Related Posts

-

2025 How to Choose the Right Steel Ball Valve for Your Industrial Needs

-

The Rising Demand for Globe Valves in Industrial Applications and Their Key Performance Metrics

-

Top 10 Reasons Why Steel Ball Valves Are Essential for Your Industrial Applications

-

Top 10 Industrial Valves Every Engineer Should Know About

-

Understanding the Essential Role of Trunnion Valves in Modern Industrial Applications

-

How to Choose the Right Swing Check Valve for Your Plumbing Needs