10 Essential Tips for Choosing the Right Trunnion Valve

Choosing the right trunnion valve can significantly impact system performance. According to industry expert Dr. James Whitaker, "Selecting the correct valve for your application is crucial." His insights into trunnion valves highlight the importance of understanding specific needs.

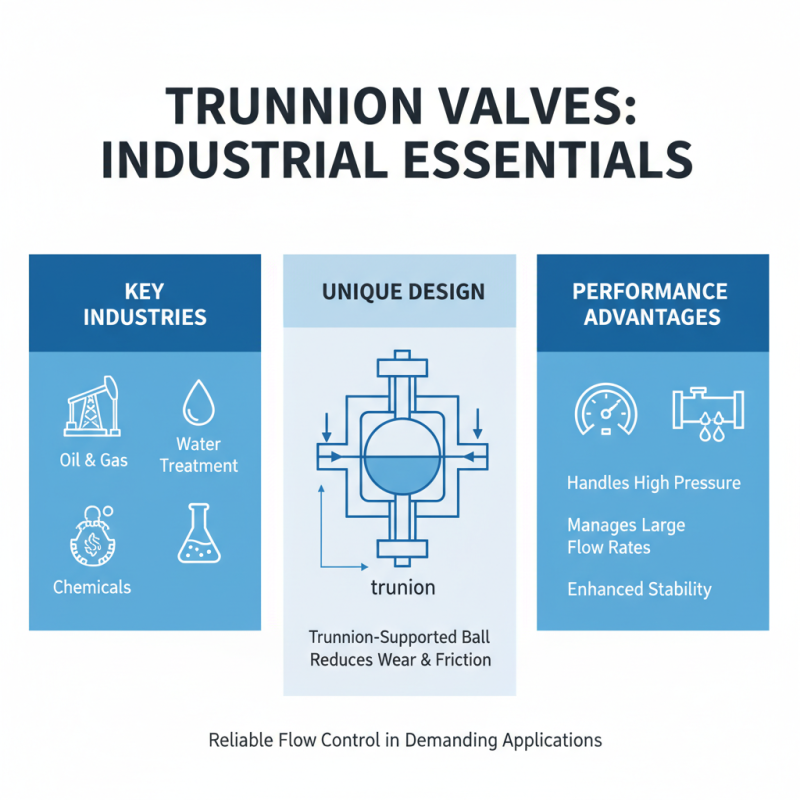

Trunnion valves are known for their ability to handle high pressures and large flow rates. They feature a unique design where the ball is supported by trunnions, providing stability and reducing wear. However, the selection process can be complex. Factors like material choice, pressure rating, and size play a vital role.

Many professionals overlook maintenance needs. This can lead to costly errors. A careful approach must be taken. It's essential to consider the environment where the valve will operate. Understanding these aspects will guide you in making informed decisions. Ultimately, a well-chosen trunnion valve contributes to the efficiency and longevity of your system.

Understanding Trunnion Valves and Their Applications

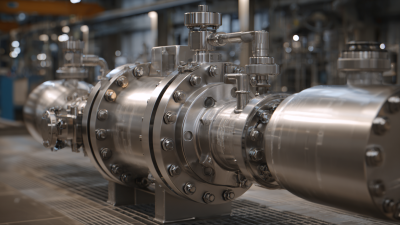

Trunnion valves are essential in many industries, including oil and gas, water treatment, and chemicals. These valves feature a unique design that allows them to handle high pressure and large flow rates effectively. Their structure involves a trunnion that supports the ball, providing stability and reducing wear over time. This stability is critical in applications where pressure changes occur frequently.

When considering the application of trunnion valves, it's crucial to evaluate the operating environment. Factors like temperature, pressure, and the type of fluid should guide your choice. Understanding these elements can enhance performance and longevity. Often, companies overlook the specific conditions in which the valve will operate. This oversight can lead to ineffective results or even valve failure.

Furthermore, the installation process can impact performance. A wrongly installed valve may lead to leaks or improper functioning. Regular maintenance checks are also vital in ensuring the valve operates efficiently. However, many users neglect this aspect, leading to increased downtime. It’s important to be aware of these details; each aspect can significantly impact overall system reliability.

Key Factors to Consider When Selecting a Trunnion Valve

Choosing the right trunnion valve requires careful consideration of various factors. Understanding your specific application is key. The valve must meet pressure and temperature requirements. Always check the materials of construction. Corrosion resistance is essential in harsh environments. A mismatch can lead to premature failure.

One important tip is to assess the valve's size and flow characteristics. Ensure it matches your piping system. If the valve is too large or too small, it may not perform efficiently. This could impact the entire operation. Additionally, consider the sealing mechanism. A reliable seal prevents leaks and ensures safety.

Don’t overlook the installation and maintenance needs. Some valves require more effort to install and maintain. Ensure your team has the right skills. Lastly, review supplier support options. A good supplier can help you navigate any challenges. Always evaluate feedback and reviews from other users. This information can guide your decision-making process significantly.

10 Essential Tips for Choosing the Right Trunnion Valve

Materials and Design Considerations for Durability

When selecting a trunnion valve, materials and design play crucial roles in its durability. The right material can withstand high pressure and corrosive environments. Common materials include stainless steel, carbon steel, and special alloys. Each option has unique strengths. Consider the specific application and environment.

Tip: Choose materials based on the fluid type. This is critical for longevity. For example, corrosive fluids need resistant materials. Your choices will impact performance over time.

Design aspects also matter. A well-designed valve reduces wear and tear. Look for features like anti-blowout stems and effective sealing mechanisms.

Tip: Pay attention to the valve's pressure rating. It should match your system's needs. A mismatch can lead to failure, which is costly. Reflect on your system's demands before making a choice.

10 Essential Tips for Choosing the Right Trunnion Valve - Materials and Design Considerations for Durability

| Tip | Material Consideration | Design Feature | Durability Rating |

|---|---|---|---|

| 1. Assess Operating Conditions | Carbon Steel | Straight Bore Design | Moderate |

| 2. Choose Corrosion Resistance | Stainless Steel | Dual-Block Design | High |

| 3. Consider Temperature Variations | Alloy Steel | Thermal Insulation | High |

| 4. Verify Pressure Ratings | Ductile Iron | Heavy-Duty Design | Very High |

| 5. Evaluate Size & Weight | PVC | Lightweight Design | Moderate |

| 6. Check for Maintenance Needs | Brass | Easy Access Design | High |

| 7. Explore Lifespan Assurance | Nickel Alloy | Reinforced Body | Very High |

| 8. Review Standards Compliance | ASTM Standard Materials | Standardized Testing | High |

| 9. Analyze Flow Efficiency | Plastic Composites | Optimized Flow Path | Moderate |

| 10. Select Control Options | Titanium | Smart Control System | Very High |

Operating Conditions and Pressure Ratings for Trunnion Valves

When selecting trunnion valves, understanding operating conditions and pressure ratings is vital. Trunnion valves are designed for high-pressure applications. According to industry reports, the pressure rating can range from ANSI 150 up to ANSI 2500 and higher. At higher pressure ratings, durability and reliability become essential.

Operators must consider temperature and fluid type. Some reports indicate that temperature fluctuations can affect valve performance. For instance, when operating at temperatures above 200°C, special materials may be necessary. Standard materials might not withstand extreme conditions, leading to failures.

An effective choice hinges on these parameters. Many engineers overlook the specifics of operating conditions, assuming standard ratings suffice. However, this can lead to unexpected problems in the field. It’s important to reflect on past experiences with valve failures due to inadequate pressure ratings. Understanding these elements can result in better long-term performance.

Maintenance Requirements and Lifespan of Trunnion Valves

When selecting a trunnion valve, understanding its maintenance requirements is crucial. Regular inspection is vital to ensure the valve operates efficiently. It is often overlooked, leading to unexpected failures. A simple visual check can reveal signs of wear or corrosion.

Lifespan greatly varies based on usage and environmental conditions. In harsh environments, the lifespan can shorten significantly. Proper lubrication and timely repairs are key to extending the valve’s life. Neglect can result in costly downtime.

It's important to develop a maintenance schedule tailored to specific operational conditions. Many facilities skip this step, thinking it’s unnecessary. However, a proactive approach can mitigate risks. Monitoring performance helps in making informed decisions about repair or replacement. Don't wait until it’s too late to address issues. Regular upkeep is an investment in reliability.

Related Posts

-

Understanding the Essential Role of Trunnion Valves in Modern Industrial Applications

-

How to Choose the Right Trunnion Ball Valve for Your Application

-

How to Create a Floating Ball Experiment: Fun Physics Activities

-

Top 10 Benefits of Trunnion Mounted Ball Valve for Your Industrial Applications

-

Why Does a Floating Ball Defy Gravity in Water?

-

Top 10 Ball Valves for Industrial Applications You Should Consider