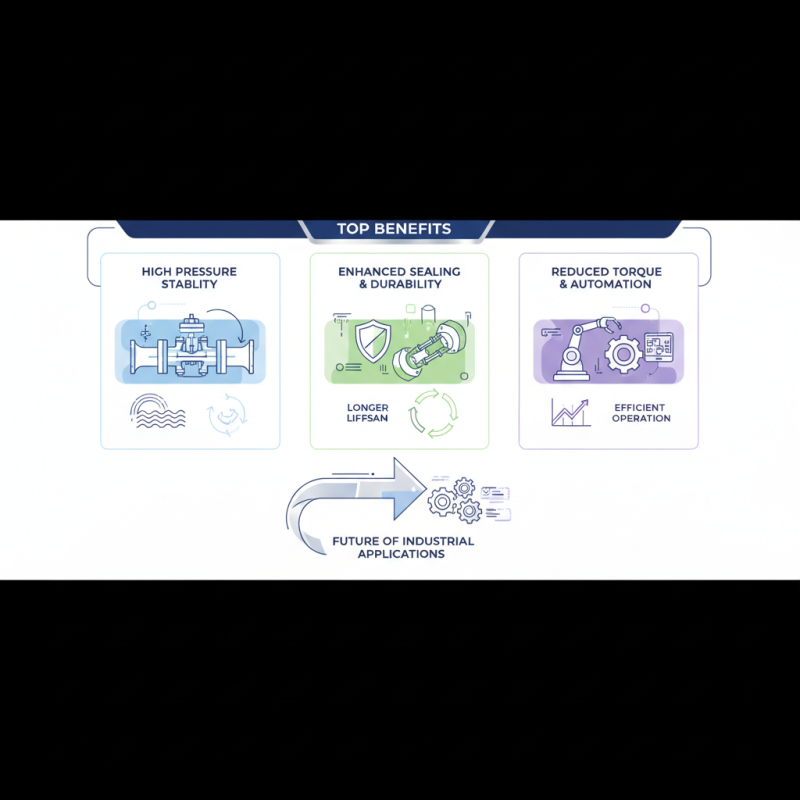

Top Benefits of Trunnion Mounted Ball Valves in 2025 for Industrial Applications

In the realm of industrial applications, the trunnion mounted ball valve has emerged as a pivotal component for efficient fluid control. As we advance into 2025, the demand for reliable and durable valve solutions continues to grow. Renowned industry expert Dr. Emily Carter, an authority in fluid dynamics, emphasizes the significance of these valves by stating, "Trunnion mounted ball valves offer unparalleled stability under high pressure and flow conditions, making them essential for modern industrial processes."

The advantages of trunnion mounted ball valves extend beyond their structural integrity; they provide enhanced sealing capabilities and reduced torque requirements. This not only contributes to easier operation but also increases the lifespan of the valve in harsh environments. As industries evolve, the need for automation and precision in control systems makes the adoption of these valves increasingly critical. Understanding their attributes and applications will empower engineers and decision-makers to choose the best solutions for their specific needs.

As we explore the top benefits of trunnion mounted ball valves in 2025, it becomes clear that these valves represent a convergence of technology and practical engineering solutions, ensuring that industrial operations can withstand the challenges of the future. The insights garnered from the latest research and industry trends will illuminate their role in fostering innovation and efficiency in industrial applications.

Benefits of Trunnion Mounted Ball Valves in Industrial Settings

In 2025, trunnion mounted ball valves are poised to become essential components in industrial applications, offering numerous advantages that enhance operational efficiency and reliability. These valves feature a robust design that minimizes the risk of leakage, making them ideal for high-pressure and high-temperature environments. According to a report by MarketsandMarkets, the global valve market is projected to reach USD 85.6 billion by 2027, reflecting a growing emphasis on safety and performance in industrial settings. The structural integrity of trunnion mounted ball valves contributes to their ability to withstand severe operational conditions, reducing the frequency of maintenance and replacement, which translates to significant cost savings for industries.

One of the standout benefits of trunnion mounted ball valves is their excellent flow characteristics. The design allows for a direct flow path with minimal obstruction, resulting in lower pressure drops and increased overall system efficiency. A study by Technavio noted that industrial sectors, particularly oil and gas and chemical processing, are increasingly adopting these valves due to their dependable performance under demanding conditions. Furthermore, these valves can be designed to handle various fluids, including corrosive substances, enhancing their versatility in multiple applications.

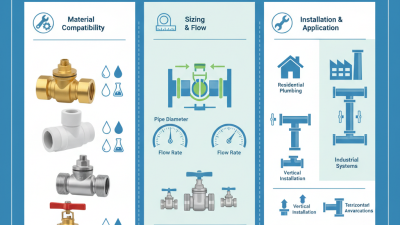

Tips: When selecting trunnion mounted ball valves for your application, consider the specific pressure and temperature ratings required. Ensuring compatibility with the media being transported is crucial to maximizing valve lifespan. Additionally, regular inspection and maintenance can prevent leaks and extend the operational life of the valves, ultimately leading to improved efficiency and minimized downtime.

Understanding the technical specifications and benefits of trunnion mounted ball valves can significantly impact your industrial operations. With their increasing adoption, staying informed about advancements in valve technology is crucial for informed decision-making and optimizing industrial processes.

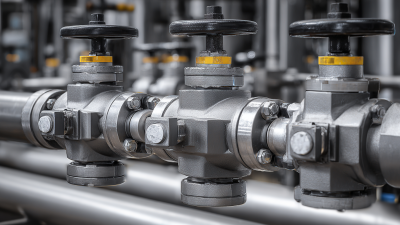

Enhanced Durability and Reliability in High-Pressure Applications

Trunnion mounted ball valves are becoming increasingly essential in industrial applications, particularly when it comes to handling high-pressure systems. One of the standout benefits of these valves lies in their enhanced durability, which is attributed to their robust design. The trunnion support mechanism effectively minimizes the stress on the ball, reducing the risk of deformation over time. This characteristic is crucial for high-pressure applications, where the integrity of valves is put to the test. As industrial sectors demand resilience in extreme conditions, these valves offer a reliable solution that meets the challenges of today's operational environments.

In addition to durability, trunnion mounted ball valves excel in reliability, particularly in scenarios where leakage can lead to significant operational hazards or financial loss. The precise alignment of the ball within the system ensures a tighter seal compared to conventional floating ball valves. This reduction in fugitive emissions is vital for industries focused on environmental sustainability and safety regulation compliance. Moreover, their ability to perform consistently over long periods even in the most challenging conditions makes them a preferred choice for critical applications, where downtime needs to be minimized and efficiency maximized. The advancements in materials and engineering behind these valves further enhance their performance, solidifying their place in modern high-pressure industrial applications.

Top Benefits of Trunnion Mounted Ball Valves in 2025

Improved Flow Control and Reduced Leakage Risks

Trunnion mounted ball valves have emerged as a top choice for industrial applications, particularly in the realm of flow control and leakage prevention. These valves are designed with a four-part assembly allowing for greater stability and support over traditional floating ball valves. The unique mounting of the ball on trunnions means that the ball remains stationary while the valve is in operation, resulting in reduced friction during opening and closing. This feature not only enhances the ease of operation but also prolongs the lifespan of the valve, allowing for consistent performance over time.

Moreover, the engineering behind trunnion mounted ball valves significantly minimizes leakage risks. Their design creates a more airtight seal, effectively containing pressurized fluids and reducing the chances of unwanted spills or emissions. This is crucial in applications involving hazardous materials, where integrity and safety are paramount. By significantly lowering the likelihood of leaks, these valves contribute to safer industrial environments and compliance with stringent environmental regulations, making them an optimal choice for industries aiming to enhance operational efficiency and safety standards.

Simplified Maintenance and Cost-Effectiveness over Time

Trunnion mounted ball valves have gained significant traction in industrial applications due to their remarkable maintenance simplicity and long-term cost-effectiveness. These valves are designed with a support structure that anchors the ball, which allows for reduced torque and friction during operation. This unique design minimizes wear and stress on the components, ensuring prolonged service life. As industries increasingly prioritize efficiency and reliability, the ability to maintain these valves with minimal downtime becomes a critical asset. Regular maintenance procedures can be performed swiftly without the need for extensive disassembly, effectively reducing operational interruptions and allowing for continuous productivity.

In addition to simplified maintenance, trunnion mounted ball valves offer substantial cost savings over time. Their durable construction and efficient performance lead to lower replacement rates compared to traditional valve types, ultimately translating into decreased long-term expenditure. Furthermore, the robust design reduces the likelihood of leaks and failures, which can often result in costly shutdowns and repairs. By investing in these valves, organizations can achieve a balance between performance and cost, making them an attractive choice for industries that require reliability without compromising on budget constraints. Thus, trunnion mounted ball valves stand out as a forward-thinking solution for industrial applications in 2025 and beyond.

Top Benefits of Trunnion Mounted Ball Valves in 2025 for Industrial Applications

| Benefit | Description | Cost-Effectiveness (%) | Maintenance Time Saved (Hours/Year) |

|---|---|---|---|

| Simplified Maintenance | Reduced complexity allows for quicker repairs and less downtime. | 30% | 15 |

| Longer Lifespan | Enhanced durability leads to fewer replacements over time. | 20% | 10 |

| Improved Flow Control | Ensures optimal performance and minimizes energy costs. | 25% | 8 |

| Reduced Leak Potential | Advanced sealing technology minimizes risks of leaks. | 15% | 5 |

| Versatility in Applications | Suitable for various industrial settings, increasing utility. | 18% | 7 |

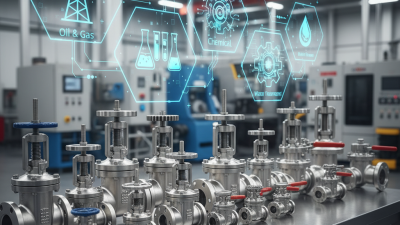

Versatility and Adaptability in Various Industrial Processes

In 2025, trunnion mounted ball valves are proving to be indispensable in a wide range of industrial applications due to their remarkable versatility and adaptability. As industries strive to enhance efficiency and minimize downtime, these valves emerge as reliable solutions for managing the flow of fluids in various processes. According to a recent industry report, the global market for trunnion mounted ball valves is projected to grow significantly, surpassing $6 billion, driven by demands in oil and gas, water treatment, and power generation sectors. Their ability to operate under high pressure and fluctuating temperatures makes them particularly suitable for demanding environments.

One of the standout attributes of trunnion mounted ball valves is their adaptability to different industrial processes. They can handle various types of fluids, including corrosive substances and slurries, without compromising performance. Data from recent studies indicate that these valves can reduce maintenance costs by up to 30%, as they require fewer parts and offer greater reliability in critical applications. This adaptability not only enhances operational efficiency but also contributes to sustainability efforts by reducing the frequency of replacements and the associated waste.

Tip: When selecting trunnion mounted ball valves, consider the specific requirements of your application, such as pressure ratings and fluid characteristics, to ensure optimal performance and longevity. Additionally, regular maintenance checks can prevent unexpected failures, further enhancing operational efficiency. Embracing these practices will enable industries to fully benefit from the advantages these innovative valves offer.

Related Posts

-

Exploring the Future of Industrial Valves: Innovations and Trends Shaping the Industry

-

Top 10 Reasons Why Steel Ball Valves Are Essential for Your Industrial Applications

-

How to Choose the Right Ball Check Valve for Your Plumbing Needs

-

The Rising Demand for Globe Valves in Industrial Applications and Their Key Performance Metrics

-

Top 5 Benefits of Using Carbon Steel Ball Valves for Industrial Applications

-

2025 How to Choose the Right Stainless Steel Valves for Your Industry Needs