2025 Top Insights: Ball Valve vs Globe Valve - Which is Best for Your Project?

In the ever-evolving world of industrial valve technologies, the decision between a ball valve and a globe valve can significantly impact the efficiency and effectiveness of any project. According to a recent report by the Global Valve Market Analysis, the demand for both ball valves and globe valves is projected to grow substantially, driven by advancements in automation and the need for reliable flow control systems across various sectors. In particular, the ball valve is renowned for its low friction loss and quick operation, often ideal for on/off applications, while the globe valve is favored for its superior throttling capabilities, making it a preferred choice for flow regulation.

As professionals navigate the intricate landscape of fluid control, understanding the fundamental differences and applications of ball valves versus globe valves becomes crucial. Research from the American Society of Mechanical Engineers highlights that ball valves typically excel in applications requiring minimal pressure drop, whereas globe valves provide better control of flow rates due to their design, which allows for precise adjustment. This article will delve deeper into these insights, comparing both valve types based on critical performance metrics to help you determine which is best for your specific project needs. By leveraging these industry trends and data, decision-makers can make informed choices that align with operational goals and budget considerations.

Overview of Ball Valves and Globe Valves

Ball valves and globe valves serve critical roles in fluid regulation and control across various industrial applications, and understanding their differences is essential when selecting the right type for a project. A ball valve employs a spherical disc to control fluid flow, allowing for quick shut-off and minimal pressure loss. According to a recent market analysis by Grand View Research, the global ball valve market is projected to grow at a CAGR of 5.5% from 2020 to 2027, driven by their high reliability and low maintenance requirements. This makes ball valves particularly advantageous in applications requiring frequent on-off control, such as in oil and gas pipelines, where efficiency and safety are paramount.

On the other hand, globe valves are designed with a linear motion mechanism for fine control of fluid flow. Their unique design provides better throttling capability compared to ball valves, making them suitable for applications where precise flow adjustments are necessary. A report by Research and Markets indicates that the globe valve market is expected to witness a CAGR of 4.2% during the same period due to the increasing demand for better flow management in power generation and chemical processing industries. Understanding these characteristics allows project managers to tailor valve selection based on specific operational demands, ensuring optimal system performance and longevity.

Key Differences Between Ball Valves and Globe Valves

When comparing ball valves and globe valves for engineering projects, understanding their key differences is paramount for making an informed decision. Ball valves are renowned for their ability to provide a tight seal and allow for quick on-off control with minimal pressure drop. According to a report from ResearchAndMarkets, the global ball valve market is projected to grow at a CAGR of 5.2% from 2020 to 2025, driven by their increasing application in fluid control across various industries, including oil and gas, water treatment, and HVAC systems.

On the other hand, globe valves are favored for their throttling capabilities and versatility in flow regulation. They are particularly effective in applications where flow control is crucial, although they tend to have a higher pressure drop compared to ball valves. A study by Mordor Intelligence indicates that the globe valve market is anticipated to see a growth rate of 4.5% during the same period, with key demand stemming from power generation and chemical processes where precise flow management is essential.

Overall, the choice between ball valves and globe valves will significantly depend on the specific requirements of the project at hand, including considerations of flow control, pressure drop, and leak-tight performance. The comprehensive analysis of these features can lead to enhanced operational efficiency and reduced maintenance costs in industrial systems.

2025 Top Insights: Ball Valve vs Globe Valve - Which is Best for Your Project?

| Feature | Ball Valve | Globe Valve |

|---|---|---|

| Flow Direction | Bi-directional | Uni-directional |

| Pressure Drop | Low | High |

| Maintenance | Low | Moderate |

| Operation Speed | Fast (¼ turn) | Slow (multiple turns) |

| Applications | On/off control | Regulation of flow |

| Size Range | ½ inch to 48 inches | ½ inch to 24 inches |

| Sealing | Tight sealing | Good sealing |

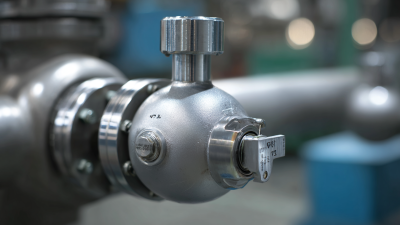

Advantages of Using Ball Valves in Projects

In the realm of industrial applications, ball valves are increasingly favored for their superior performance and reliability. According to a recent market analysis by Frost & Sullivan, the global ball valve market is projected to grow at a CAGR of 5.2% from 2021 to 2028, driven primarily by the widespread adoption of these valves in the oil and gas sectors. One of the main advantages of ball valves is their low-pressure drop, which allows for smoother fluid flow. This feature is essential in various projects where efficiency and speed are paramount.

Additionally, ball valves offer excellent sealing capabilities, which contribute to their durability and reliability in high-pressure environments. A study published in the Journal of Pressure Vessel Technology indicates that ball valves maintain a sealing efficiency of over 95% when properly maintained, making them a preferred choice for critical applications. Moreover, their compact design and ease of automation further enhance their suitability for modern projects, where space and control are significant factors. These attributes make ball valves not only a pragmatic option but also a smart investment for engineers and project managers looking to optimize functionality and sustainability in their systems.

Advantages of Using Globe Valves in Projects

Globe valves are often favored in various projects due to their superior flow control capabilities. One of the primary advantages of using globe valves is their ability to provide precise throttling. Unlike ball valves, which are designed for on/off service, globe valves can regulate flow rate effectively. This feature makes them ideal for applications where controlling the flow is critical, such as in fuel transfer or chemical processing. Their design allows for a greater surface area for seating, which contributes to a tighter seal and minimizes leakage.

Additionally, globe valves are versatile in terms of installation and orientation. They can be employed in both horizontal and vertical piping systems without compromising performance, making them suitable for a wide range of industrial applications. Their robust construction also enhances durability, ensuring longevity under high pressure and temperature conditions. Given these advantages, globe valves emerge as an optimal choice for projects that require reliable and adaptable flow regulation.

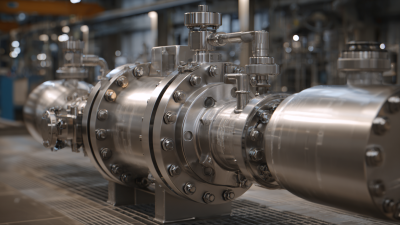

Application Scenarios for Ball Valves vs Globe Valves

When choosing between ball valves and globe valves for your project, it’s essential to consider the specific application scenarios each valve type serves best.

Ball valves are often preferred in situations where quick shut-off is necessary. They operate with a straightforward 90-degree turn, making them ideal for high-flow applications in industrial settings. Their design allows for minimal pressure drop and outstanding sealing capabilities, making them suitable for services that require tight closure and rapid flow regulation.

On the other hand,

globe valves excel in applications needing precise flow control and throttling capabilities. Their unique design enables them to provide finer adjustment of flow rates, making them perfect for processes such as water distribution, power generation, and chemical processing. While globe valves may create more pressure loss due to their flow path, they offer better reliability in modulating flow, which can be essential in certain systems requiring consistent performance under varying pressures.

Selecting the right type depends heavily on the specific demands of your project, including flow requirements, pressure conditions, and the nature of the media being controlled.

Related Posts

-

10 Best Ball and Globe Valves for Optimal Fluid Control in Industrial Applications

-

The Rising Demand for Globe Valves in Industrial Applications and Their Key Performance Metrics

-

What is a Stainless Steel Globe Valve and Its Key Benefits for Industries

-

Understanding the Essential Role of Trunnion Valves in Modern Industrial Applications

-

Top 5 Pressure Valves: Choosing the Best for Your Industrial Needs

-

2025 How to Choose the Right Stainless Steel Valves for Your Industry Needs