2026 Best Ball Valve with Check Valve for Efficient Fluid Control?

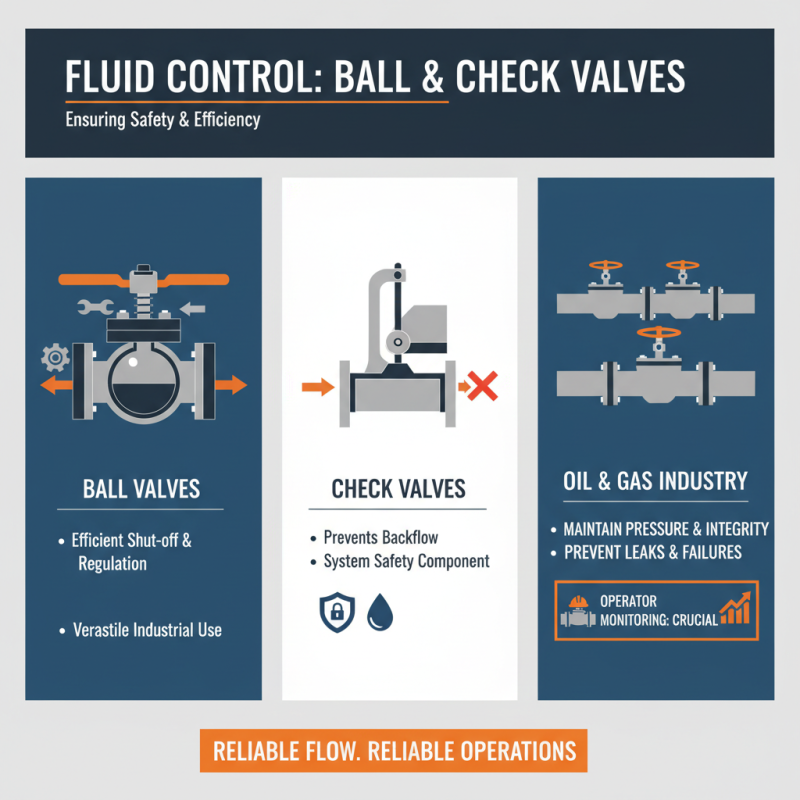

In the evolving landscape of fluid control systems, the importance of a reliable ball valve with check valve has become clearer. Industry reports indicate that the demand for efficient fluid management solutions has surged by 15% over the past five years. Engineers and designers prioritize systems that minimize leaks and enhance operational reliability. Ball valves with integrated check valves serve this purpose well, preventing backflow while ensuring smooth fluid movement.

Manufacturers are now focusing on advanced materials and innovative designs. This evolution aims to improve performance in critical applications such as pipelines and industrial machinery. However, challenges remain; not all ball valves with check valves are created equal. Quality varies across products, and choosing the right one is crucial for long-term efficiency. Neglecting this can lead to costly downtime and repair.

As the world shifts towards more sustainable practices, the role of dependable fluid control systems becomes paramount. Reports indicate that technological advancements could enhance the efficiency of ball valves with check valves by up to 20%. This presents an opportunity for industry stakeholders to rethink their approaches and invest in better solutions. Evaluating products carefully is essential to ensure effective fluid control in diverse applications.

Overview of Best Ball Valves with Check Valves in 2026

In 2026, ball valves with check valves are gaining attention for efficient fluid control. Their design allows for a quick shut-off feature, making them essential in various industries. According to a recent market analysis, the demand for these valves is projected to grow by 10% annually. This growth reflects a shift towards more reliable and safer fluid handling systems.

These valves are versatile, handling different types of fluids and pressures. Many sectors, such as oil and gas and water treatment, rely on them. However, not all configurations perform equally. Some installations may lead to backflow issues. This can cause costly downtime and repairs. It’s crucial to choose the right combination for specific applications.

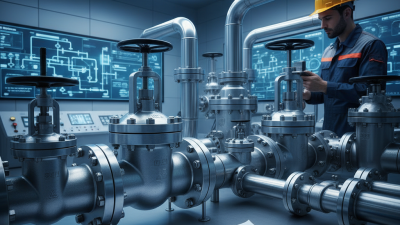

Maintenance remains a critical factor in their effectiveness. Routine checks can help reduce failures. An industry report suggested that over 30% of valve issues were due to wear and improper installation. Continuous education on best practices is essential. Ultimately, while these valves represent advanced fluid control, their implementation requires careful consideration.

Key Features of Efficient Fluid Control in Ball Valves

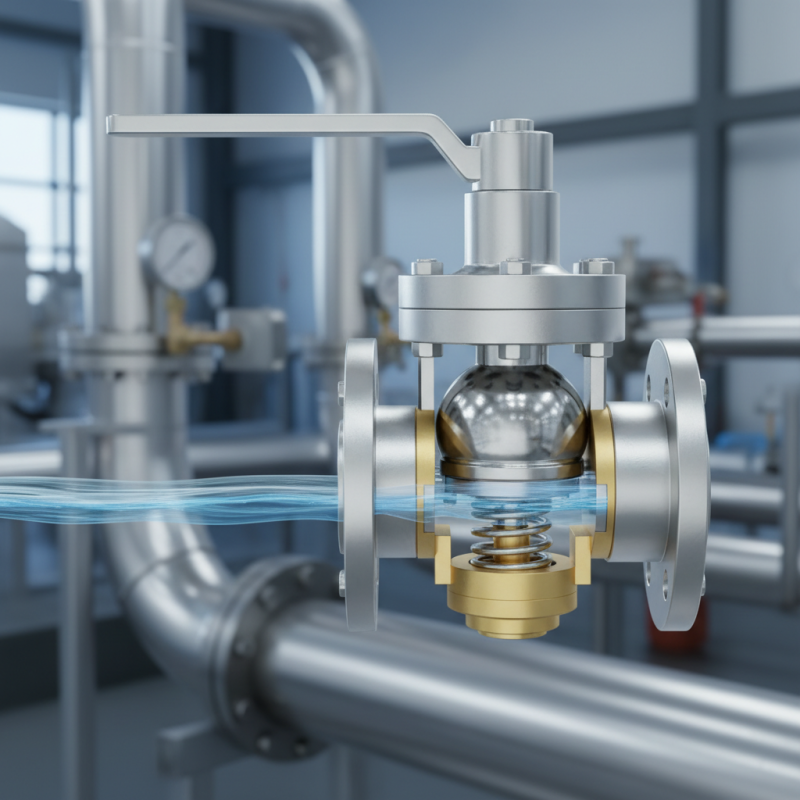

Ball valves with check valves are critical for efficient fluid control. They enhance the flow management in various systems. Their design allows for quick and reliable shut-off, making them essential for industrial applications. One notable feature is the integrated check valve. It prevents backflow, ensuring that fluids flow in one direction only. This reduces the risk of contamination and system failure.

The sealing mechanism is another important aspect. Many ball valves use durable materials that withstand high pressure. This durability is crucial for maintaining system integrity. However, one must be cautious. Over time, seals can wear out, leading to leaks. Regular maintenance is key to ensuring optimal performance.

In terms of installation, precision is necessary. Poor alignment can lead to uneven wear and tear. It’s essential to follow the manufacturer’s guidelines during setup. Simplifying the operation can also enhance efficiency. Using actuators can automate the flow control. Yet, it’s important to assess the system's unique needs before making such decisions. These are just a few considerations to keep in mind.

2026 Best Ball Valve with Check Valve for Efficient Fluid Control

| Feature | Description | Benefit |

|---|---|---|

| Material Quality | Made from durable stainless steel or PVC | Enhanced resistance to corrosion and chemical damage |

| Check Valve Integration | Built-in check valve to prevent backflow | Increased safety and reliable fluid control |

| Temperature Range | Operational range from -20°C to 150°C | Versatile use in various applications |

| Pressure Rating | Rated for 150 psi | Suitable for high-pressure applications |

| Actuation Options | Manual and automated actuation available | Improved ease of use and efficiency |

| Seal Design | High-performance seals for leak prevention | Maximized reliability and reduced maintenance |

Comparative Analysis of Popular Ball Valve Models with Check Valves

When selecting a ball valve with a check valve, comparing popular models is essential. Many types exist, each with unique features. Some are designed for high pressure, while others excel in low-flow applications. Understanding these differences helps in making informed decisions.

For instance, one model may offer a compact design, ideal for limited spaces. Another might have a larger diameter, providing better flow rates. Users often overlook these variations. Sometimes, a more extensive model may seem better but can be cumbersome in tight installations.

It's also crucial to assess materials used in construction. Metal valves might tolerate higher temperatures but can corrode over time. Plastic alternatives often resist chemicals but may not handle intense pressure well. Users should balance their operational needs with maintenance requirements. So, ensuring long-term reliability can sometimes feel elusive.

Installation and Maintenance Guidelines for Ball Valves

When installing a ball valve with a check valve, proper alignment is crucial. Ensure the valve is positioned correctly to prevent leaks. Gaskets and seals should be inspected for integrity. Missing or damaged parts can lead to significant issues during operation. Using the right tools can make a difference, so invest in quality equipment.

Regular maintenance is essential for optimal performance. Check the valve periodically for signs of wear. Lubrication helps in smoothing the operation, but too much can cause buildup. Be mindful of fluid contaminants that can affect function. Every few months, a thorough cleaning of the valve will prolong its life.

Inadequate training could lead to improper installation or maintenance. If unsure, consulting professionals is advisable. It's a step that can save time and resources in the long run. Mistakes in setup can lead to inefficient fluid control. Often, addressing these missteps early can prevent larger problems later on.

2026 Best Ball Valve with Check Valve Performance Comparison

This bar chart illustrates the performance metrics of the best ball valves equipped with check valves for fluid control in 2026. It highlights key areas: flow rate, pressure drop, leakage rate, and installation time, providing an overview of efficiency in fluid control applications.

Applications of Ball Valves with Check Valves in Various Industries

Ball valves with check valves play a crucial role in various industries. These valves ensure efficient fluid control by preventing backflow. In oil and gas, they maintain pressure and integrity in pipelines. The check valve component is essential for system safety. It helps avoid costly leaks and equipment failures. Operators must monitor these valves regularly. Small issues can escalate quickly.

In the water treatment industry, these valves are vital for managing flow. They help maintain the purity of water systems. However, if improperly installed, they can cause problems. Misalignment can lead to pressure loss. Plant managers need to be vigilant. They must check connections and seals frequently. Simple maintenance can extend valve life significantly.

Manufacturing processes also benefit from these valves. They ensure that materials flow smoothly between stages. Any interruption can halt production. Workers must understand how these valves operate. Training is vital to prevent mistakes. Ignoring potential issues can lead to downtime. Investing time in employee education pays off in the long run.

Related Posts

-

Top 10 Ball Valves for Industrial Applications You Should Consider

-

Understanding the Benefits of Using Ball Check Valves in Fluid Control Systems

-

Top 5 Benefits of Using Carbon Steel Ball Valves for Industrial Applications

-

2025 How to Choose the Right Steel Ball Valve for Your Industrial Needs

-

2025 Top Insights: Ball Valve vs Globe Valve - Which is Best for Your Project?

-

Top 10 Ball Valves You Need to Know for Your Next Project